A plastic cable gland is a versatile, durable, and cost-effective solution for sealing and securing cables in a wide range of applications. It serves as a protective element that ensures cables remain safely anchored, preventing damage from environmental factors such as moisture, dust, and mechanical stress. Widely used in industries like electrical, telecommunications, and automotive, plastic cable glands are highly valued for their weather-resistant properties, ease of installation, and ability to withstand harsh conditions.

Material: Nylon PA (UL File NO: E240925).

Seal: Nitrile rubber (NBR) weather-resistant rubber (EPDM).

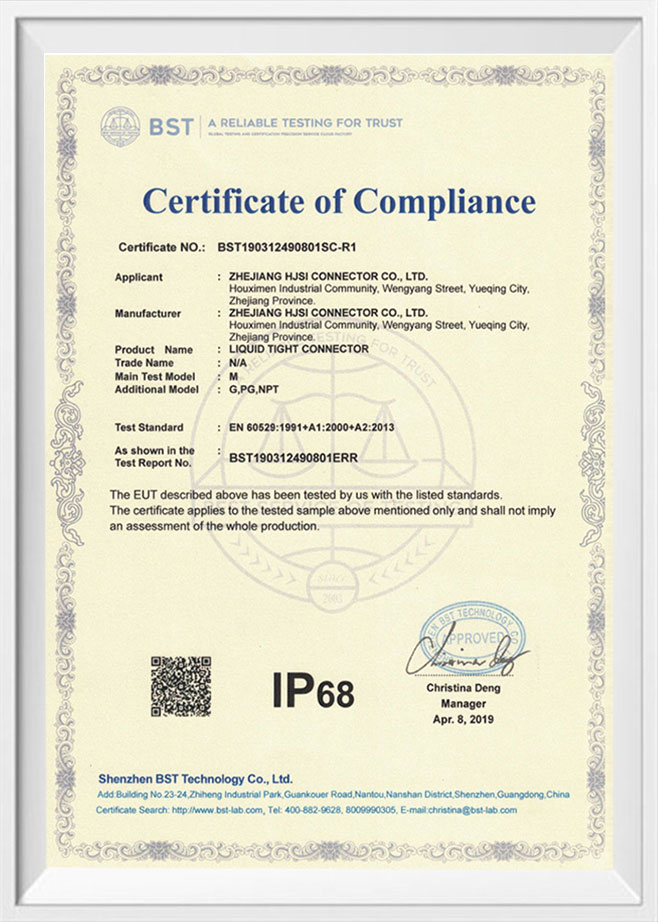

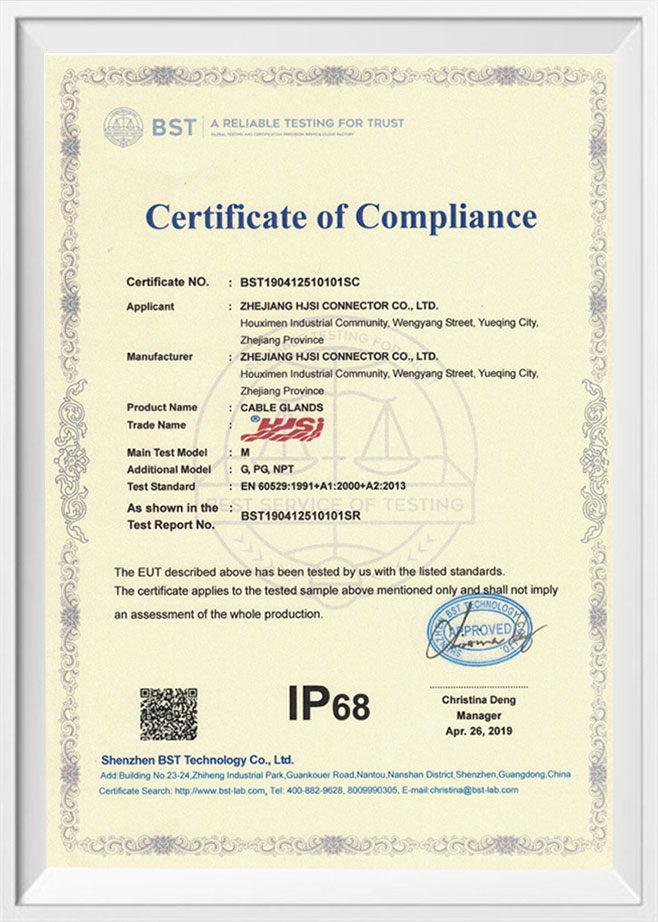

Protection grade: IP68 (tighten parts and use o-seal ring).

Ambient temperature: static 40°C to 100°C, short-term to 120°C; Dynamic 20°Cto 80°C, short-term to 100°C.

Body and Nut: PA6, Zero Halogen; Flammabity: V2,(VO optional).

Sealing and Washer: TPE.

Color: Black (RAL 9005), Light Grey (RAL 7035), Grey (RAL 7005); other colors available upon request.

IP Rating: IP68 (with thread gasket) to EN 60529.

Temperature Range: -40°C to +100°C.

Entry Thread: Metric PG.

Thread Length: Standard and Longer.

Strain Rellef: Acc.to EN 50262.

Accessory: Gland comes with Locknut, Insert Sealing, and Gasket.

Features: Wide cable range; Resistant to salt water, weak acid, alcohol, oil, grease, and common solvency.

Key Benefits of Plastic Cable Glands

Wide Cable Range Compatibility: Plastic cable glands are designed to accommodate a variety of cable sizes, ensuring a secure fit for different applications. This flexibility makes them ideal for use in a wide range of electrical installations.

Resistance to Harsh Environments: Plastic cable glands are resistant to a wide range of chemicals, including saltwater, weak acids, alcohol, oil, grease, and common solvents. This makes them particularly suitable for marine, industrial, and outdoor environments where exposure to corrosive substances is common.

Ease of Installation: The gland comes with everything needed for installation, including a locknut, insert sealing, and gasket. The design ensures that the cable gland is easy to install while providing a secure and reliable seal.

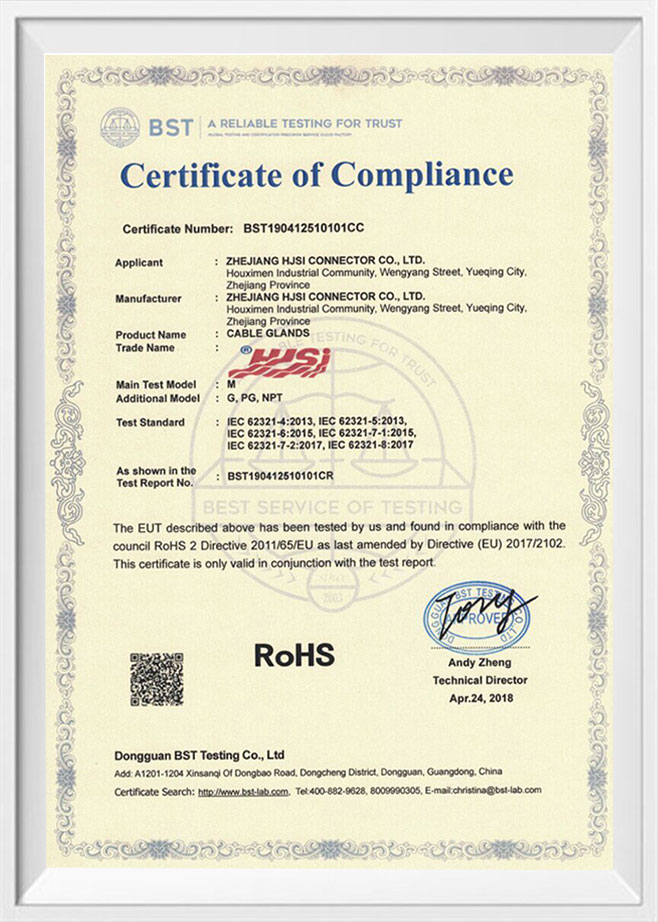

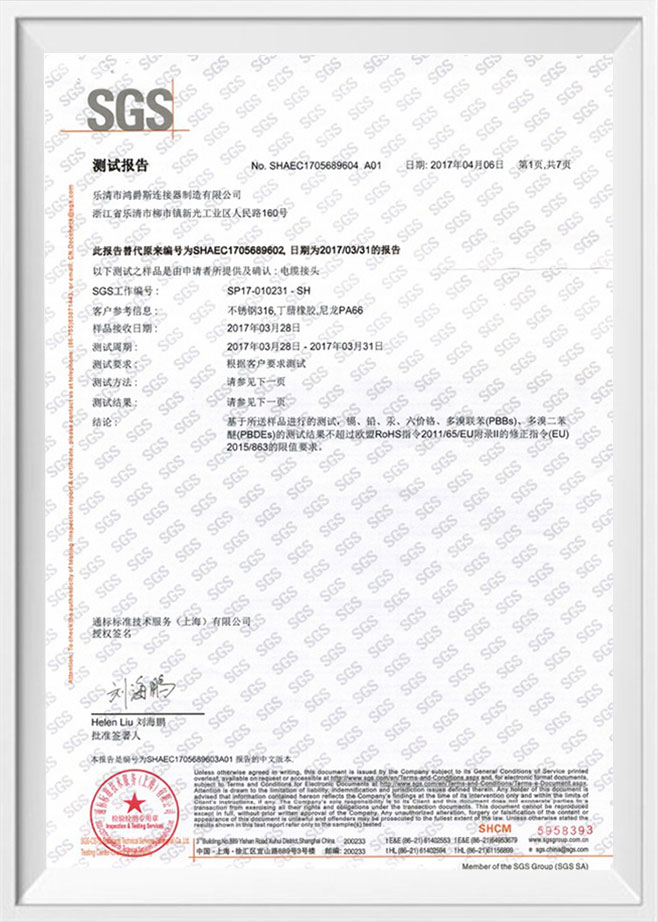

Compliance with International Standards: The plastic cable glands comply with IP68 protection standards, ensuring reliability and safety in even the most challenging conditions. They also meet the requirements of EN 50262 for strain relief, further ensuring the protection of cables in high-stress environments.

Applications of Plastic Cable Glands

Plastic cable glands are used in a variety of industries, including:

Electrical: To secure cables and ensure safe electrical connections.

Telecommunications: To protect data and signal cables from environmental damage.

Automotive: For use in automotive electrical systems that require weatherproofing and strain relief.

Marine: To prevent water ingress and protect cables in boats and ships.

Industrial: In factories and plants where cables need to be shielded from harsh chemicals and extreme conditions.

English

English русский

русский عربى

عربى